This collection features high-quality products carefully selected for our customers. Browse our selection to find exactly what you're looking for.

Why Thin Panel Cutters Matter

Standard tile cutters and saws struggle with thin panel tile and gauged porcelain because of their size, thinness, and rigidity. Thin panel cutters are designed to:

- Score and separate ultra‑large format materials cleanly

- Reduce chipping and breakage on fragile edges

- Improve productivity with precise, repeatable cuts

- Integrate easily into workshop or jobsite workflows

This collection makes it easy to find the right tool for the job — from manual scoring systems to powered rail cutters and wet saw attachments.

What You’ll Find in This Collection

Precision Scoring & Breaking Tools

Manual cutters and scoring systems for straight or repetitive cuts on thin porcelain panels. Great for contractors who value simplicity and control.

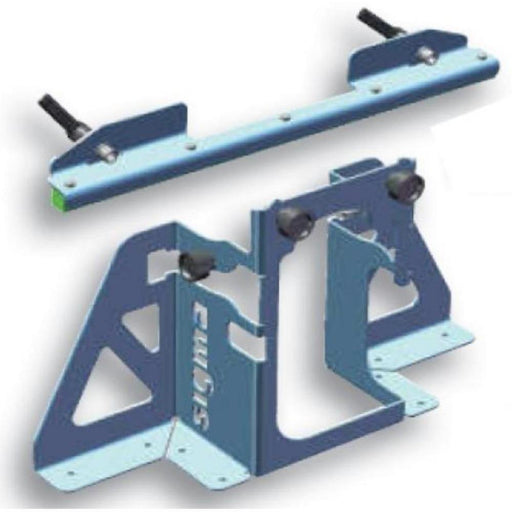

Rail Cutting Systems

Track‑guided systems for cleaner, straighter cuts on ultralarge slabs. Works well for professional workshops or jobsite fabrication.

Blade‑Ready Tools & Accessories

Diamond blades, guide rails, and replacement scoring wheels designed to work with your inspection systems and saws.

Powered Thin Panel Cutters

High‑performance cutters that use integrated scoring and splitting mechanisms for faster throughput and reduced waste.

How to Choose the Right Thin Panel Cutter

When selecting the right cutter for your project, consider:

Material Type & Thickness – Porcelain and stone require stronger scoring heads and diamond blades.

Cut Size – Long cuts on GPTP slabs benefit from rail systems or powered units.

Precision Level – For high‑accuracy projects, choose guides and rail systems over handheld cutters.

Jobsite vs Workshop – Portable systems are ideal on site, while larger rail cutters excel in controlled shop environments.