This collection features high-quality products carefully selected for our customers. Browse our selection to find exactly what you're looking for.

Thin panels raise the stakes: they’re big, they flex, and small handling mistakes can turn into cracked corners or chipped edges. The goal of a good GPTP workflow is simple—support evenly, lift safely, and control the set. This collection groups the handling gear that helps installers do exactly that, with products spanning suction/vacuum lifting, transport/positioning, and work-support solutions.

What’s in this collection

1) Suction cups & vacuum lifting solutions

Tools that improve grip and control when moving panels, aligning edges, or making micro-adjustments during the set. This includes manual suction and powered vacuum-style lifters, plus pads/seals and small accessories that keep suction performance consistent.

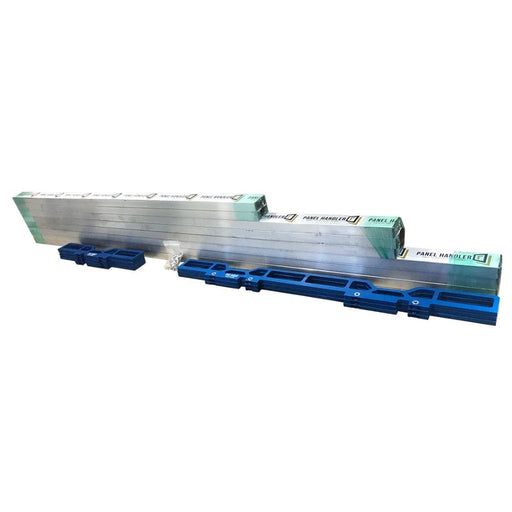

2) Panel carriers, trolleys & transport helpers

Handling systems designed to move large panels more safely—especially across the jobsite and into position—while keeping panels supported and reducing twisting loads that can lead to breaks.

3) Work tables, supports & clamping accessories

Stable work support is a big part of successful panel handling. Work tables/benches and clamps help keep panels flat during staging and prep steps so you’re not fighting flex while you work.

How to choose

- Surface type: Smooth vs. textured surfaces can affect suction performance—choose lifting solutions that match the materials you install most.

- Panel size + crew workflow: Bigger panels typically benefit from more support and more controlled transport (carriers/trolleys + reliable lifting points).

- Support before you lift: If you fabricate or stage panels on site, prioritize a stable work-support setup to reduce flex and edge stress.

- Accessories matter: Seals, pads, clamps, and small add-ons keep the “system” working consistently day after day.